Proven Systems with Unmatched Results

Incredible speed, flexibility, sanitary design, and superior customer support.

Packaging Solutions

With advances in robotics and technology, packaging robots can now do more than ever. At Propack, we offer a range of customizable robotic packaging solutions to meet the needs of each customer’s unique specifications. Whether the application is running bars, snack cakes, or frozen patty products, we have the packaging solution.

Flexibility, Reliability, and Performance

are the Cornerstone of Every Propack Machine

Robotic Loading System Features

- Handles up to 900 incoming cartons

- Servo-driven, lugless carton management system for precise carton positioning

- Quick & easy tool-less changeovers

- Rugged, sanitary frame design

- Simple integration with most flow-wrappers

- Quick, no-tool changeover for product buckets and carton size adjustment

- Cantilever infeed conveyor for easy belt removal

- Product spacing reject system removes double packs

Experience the Benefits of Our Robotic Loading Solutions

Easy-to-use operator interface

High-quality, high-speed output

Fast & efficient repeatability changeovers

Sanitary & hygienic design

Increased uptime through ease of maintenance

Flexible designs for various package sizes

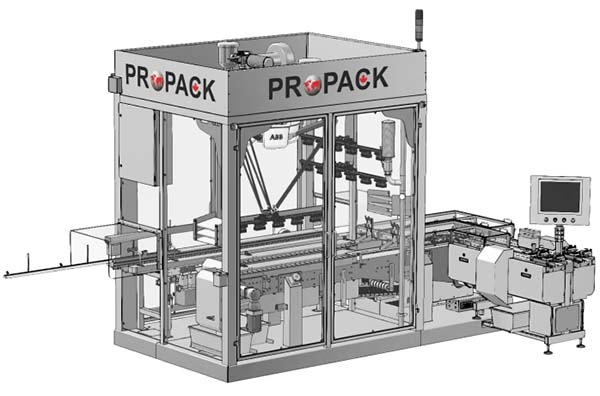

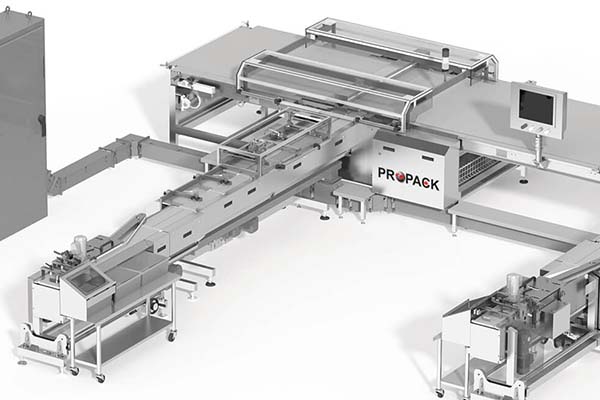

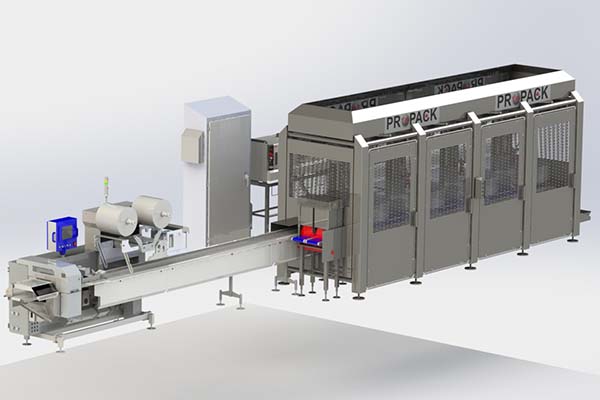

LJ-TRT Versatile Carton Loader

The ultimate in high-speed automation flexibility with an efficient, robust carton loading machine ideally suited to handle the output from medium to high-speed flow-wrappers. The LJ-TRT Dual will accurately collate your product and load into cartons, trays or multipacks. Depending on your product’s characteristics, the LJ-TRT carton loader can operate at speeds up to 900 products/min. >> Learn MoreLJ-Dual Flexible Robotic Top Loader

The LJ-TRT Dual robotic product collator and robotic top loader provides the

ultimate in automation flexibility with an efficient, robust carton loading machine ideally suited to handle the output from TWO medium-speed flow-wrappers. The LJ-TRT Dual will accurately collate your product and load into cartons, trays or multipacks. Depending on your product’s characteristics, the LJ-TRT Dual robotic top loader can operate at speeds up to 700 products/min.

>> Learn More

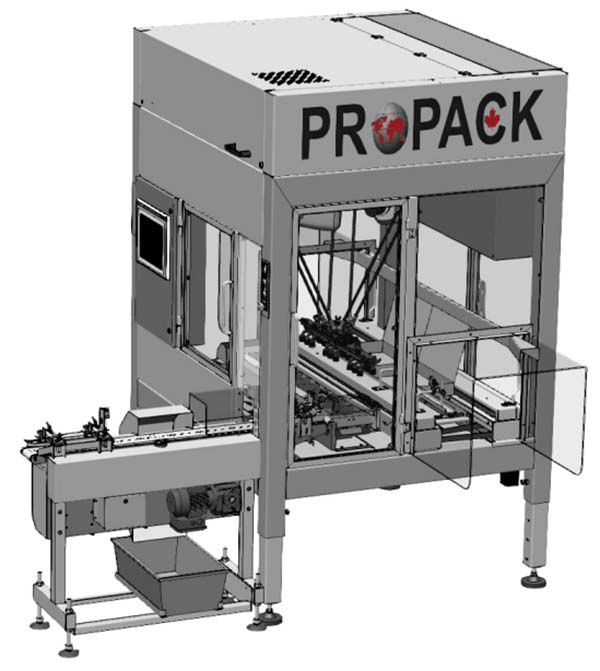

LB-SRT High Speed Tray Loader

The LB-SRT robotic product collator and robotic carton and tray loader provides the ultimate in automation value with a cost-effective, flexible carton and tray loading machine ideally suited to handle the output from medium to high-speed flow-wrappers. The LJ-TRT Dual will accurately collate your product and load into cartons, trays or multipacks. Depending on your product’s characteristics, the LB-SRT carton and tray loader can operate at speeds up to 400 products/min. >> Learn MoreLJ-QUAD TRT

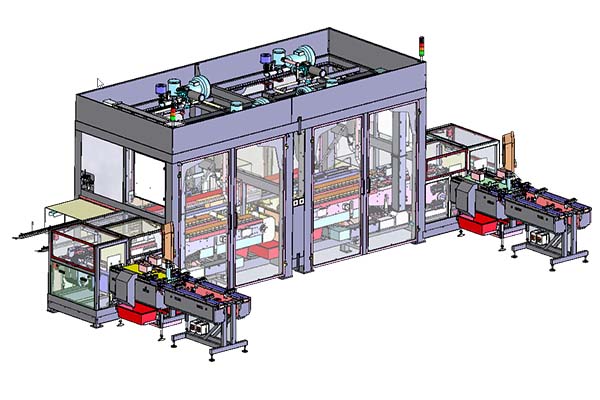

The Propack LJ-QUAD TRT provides a compact four infeed solutions for the packaging industry with the ultimate high-speed automation flexility with an efficient, robust carton loading machine ideally suited to handle the output from FOUR (4) medium to high-speed flow-wrappers.

>> Learn More

LJ-PENTA

The Propack LJ-PENTA provides a compact five infeed solution for the packaging industry with ultimate high-speed automation and flexibility, with an efficient and robust carton loading machine that is ideally suited to handle the output from FIVE (5) medium to high-speed flow-wrappers. >> Learn MorePSST/120 Synchronized Staging Transfer

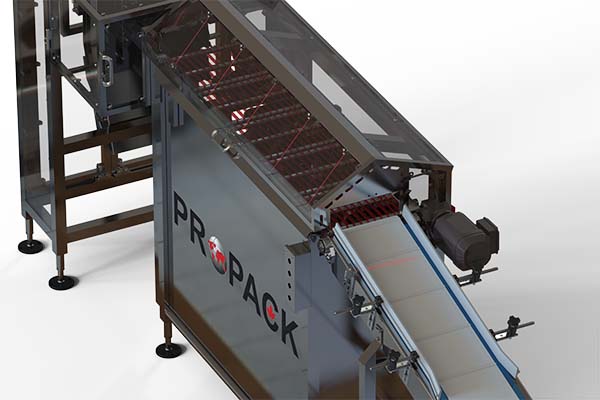

The PSST/120 is an economical, safe product delivery system that empowers the use of stepper servo technology to receive randomly produced products from baggers, pouchers and flow wrappers and synchronizes product delivery on-time, on-demand to high speed cartoning machines. Product synchronization is accomplished by intelligently monitoring and phasing products (bags, pouches, wrapped snacks, etc.) on a number of motion controlled staging sections to either a single or dual product transfer module. The Propack PSST/120 can be configured to user-defined requirements, accommodating either single, double or multi-pack formats. >> Learn MorePropack Row Distribution System

The Propack Row Distribution System is an economical, safe product delivery system that empowers the use of AC motors and servo technology to receive rows of products from upstream Processing equipment and synchronizes product delivery on-time, on-demand to low, medium, or high-speed wrapping machines. The row distribution is accomplished by intelligently monitoring product row position (bars, cookies, snacks, etc.) on a number of motion-controlled delivery sections feeding anywhere from a single or up to six wrapping machines. The Propack RDS can be configured to user-defined requirements accommodating either direct delivery, accumulation or automated refeed back into the system without operator intervention using integrated communication throughout the line. >> Learn MoreVision Systems

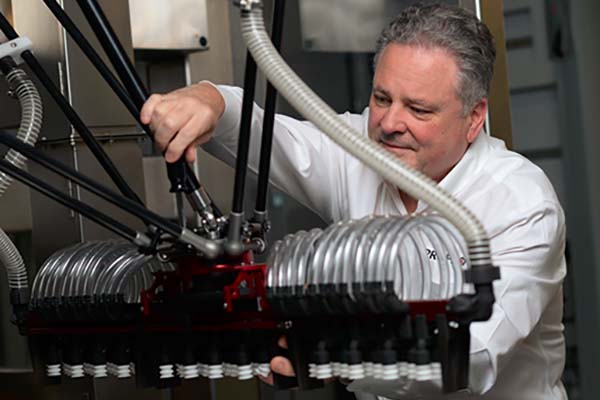

For products and applications which do not lend themselves to standard collate and load systems, Propack has developed vision aided automated systems incorporating camera technology to inspect, detect and handle products for various loading applications. Whether you are loading a cartoner, over wrapper or even in line inspection in process, we have a solution that can fit your requirement. >> Learn More

Sanitary Design

Propack systems meet and exceed every aspect of the sanitation requirements for the food processing industry.

Flexibility

Innovative and flexible designs ensure specific and unique customer needs can be met.

World Class Support

From our knowledgeable support team to our highly skilled engineers, Propack offers ongoing support both on and off-site.

Your Carton Loader Always Features an ABB Robot

Your Propack carton loader features an ABB picking robot which will handle your product with a smooth and gentle action, keeping it free from damage. Be assured that your product will be placed precisely into your carton or tray with unmatched accuracy. For years, Propack has been proud to be part of the ABB Robotics Preferred Partner Network. At the end of the day, you can be assured that your carton loader from Propack will provide the ultimate performance for your packaging operation.