Canadian packaging machine-builder leverages robotics and machine vision expertise to develop cutting-edge system solutions

This article originally appeared in Canadian Packaging, January/February 2022 edition

By George Guidoni, Editor | Photos by Naomi Hiltz

Putting vision into action is nothing new for Chris Follows, founder and president of a well-established, proudly Canadian packaging systems builder and integrator Propack Processing & Packaging Systems, Inc.

Founded in 1996, the privately-owned company has enjoyed a steadfast rise up the ranks of North American packaging machinery industry—celebrating its 25th anniversary last year with a stellar record of successful machine installations and line integration projects across major sectors of the food-and-beverage industries with exacting quality, performance and safety requirements.

Headquartered at a state-of-the-art 30,000-square-foot customer service and testing facility in Beamsville, Ont., the company operates three manufacturing locations in southern Ontario and Quebec to produce various automation components and subsystems used in its turnkey workcell automation projects, while also offering ongoing customer support from service locations in Beamsville, Halifax, Chicago and Atlanta.

“We focus our attention on the North and South American markets, which is where we can bring the most value,” Follows told Canadian Packaging on a recent visit to the Beamsville facility, which is also the central location for the company’s FAT (functional acceptance testing) validations and equipment demonstrations.

Propack Processing & Packaging Systems founder and president Chris Follows shows off some of the critical system components produced using advanced 3D printing technology, which Follows says allows the company the flexibility to make on-spec parts for its entire machinery range with exceptionally fast turnaround.

“We export approximately 70 per cent of our equipment to the United States and South America, offering machine training and documentation in Spanish to support our South American customers.

“The technology we have today allows us to support our machinery remotely, irrespective of its installation location,” Follows points out, “but with our philosophy built on the idea of exceeding our customers’ expectations at every level, this also includes making complimentary visits to the site of our older machinery ensuring they are running at peak performance.”

Says Follows: “Combining the requirements of our customers along with our innovative and patented technologies, Propack has the ability to design solutions to meet all their specific needs.”

As Follows explains, Propack primarily focuses on four strategic market segments that are highly dependent on the use of high-speed, high-throughput automated packaging lines incorporating the latest robotic and sensor technologies to crank out large volumes of energy and nutrition bars, confectioneries, pastries, snacks and other mass-produced baked goods.

Propack’s new ProVision machine employs four ABB IRB 360 FlexPacker robots to pick and place up to 400 products per minute from two running conveyor belts.

Incorporating high-end processing machinery manufactured in Canada by Sainte-Claire, Que.-based Équipements PRB—including dough dumpers; slab formers; kibblers; slitters; spreaders and guillotines—Propack has developed an exceptionally high level of expertise in integrating full turnkey lines for cold-form nutritional bar production: from early processing right through all the primary and secondary packaging stages at remarkably high speeds well in excess of 1,000 pieces per minute in continuous operation.

Sealed pouches entering the ProVision workcell are inspected by high-speed cameras to define the center of the package to ensure proper grip by the robotic tooling.

“Propack offers superior machinery that will continue to meet extraordinary production results for our customers,” Follows proclaims, citing an expansive product portfolio that includes row distribution systems, high-speed collating-and-loading systems, bag-in-box automation systems, vision-guided robotics for pick-and-place applications, and vision-based product inspection systems.

“Propack is truly committed to our customers’ success: this is rooted in our DNA,” asserts Follows.

“All our machines are engineered specifically to each project requirement to ensuring optimal performance, versatility and flexibility,” says Follows, praising the “incredible quality” of Propack’s engineering and craftsmanship widely acknowledged in the industry.

A close-up of suction vacuum cups at the end-of-arm tooling of the IRB 360 Flexpicker robots.

Says Follows: “Our attention to quality, service, support and relationships with our customers to ensure their solutions are the right ones enable us to guarantee performance.”

Built for optimal longevity, durability and sanitation, “Our machines are designed for long-time service, to exceed 100,000 hours of reliable performance,” Follows states.

“We stand behind our systems, as our customers’ success is our top priority.”

A close-up of a vacuum suction hose assembly made by an in-house 3D printer.

As an early enthusiastic adopter of industrial robotic systems, Propack’s high level of proficiency with robotic integration is rooted in its long-standing relationship with leading robotics manufacturer ABB, whose flagship IRB 360 FlexPicker series pick-and-place robots are a common feature on many machines and lines supplied and installed by Propack.

“We actually bought the very first ABB FlexPicker robot in Canada all those years ago,” Follows points out, “and it (ABB) remains the world-class robotic technology to this day.”

Not surprisingly, ABB FlexPicker robots are employed at the heart of the new ProVision pick-and-place machine that Propack launched near the end of last year—designed for high-speed secondary packaging of transparently-wrapped products with variable shapes, sizes and dimensions.

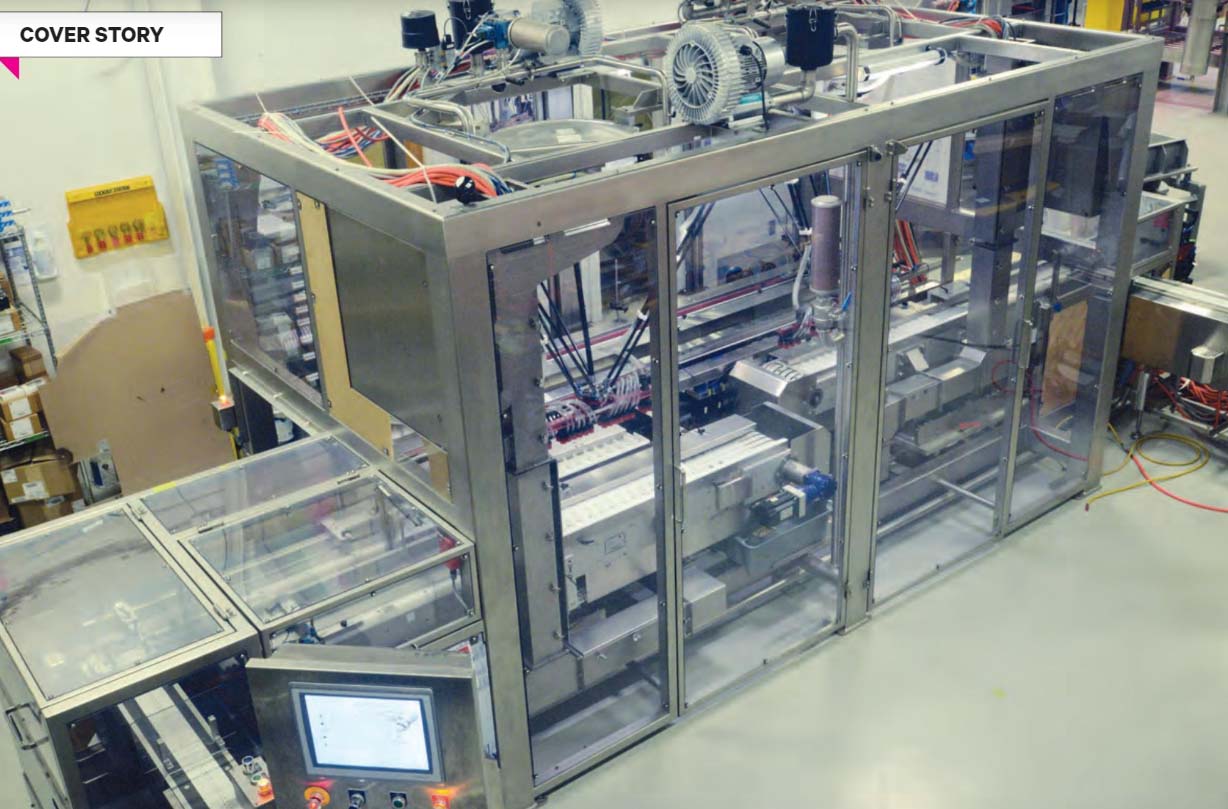

An overhead view of new hygienic packaging machine assembled at Propack’s Beamsville facility.

Featuring advanced camera technology developed in-house by Propack, the new ProVision system uses advanced image processing techniques that enables it to determine the perimeter of the package before guiding the robotic end-of-arm tooling to the center of that package each and every time.

This is especially important for packages filled with loose bulk ingredients that tend to shift and clump together inside the primary wrap before being picked up by the robots.

The ProVision camera essentially makes sure that the robot will pick up the package right at the center even if the pack’s main contents have moved off to a side or a corner of the package— thereby ensuring consistent placement for the secondary packaging process.

Follows explains, “When you have product coming out of a vertical bagger, you tend to have ‘tear dropping,’ whereby a cluster of product shifts towards one side of it.

“Whereas the typical vision systems on ABB and other robots will determine that cluster to be the center of the package,” Follow says, “our ProVision technology is able to identify the outline of the package irrespective to where the cluster is.

“It determines and identifies the perimeter of the transparent film pouches,” he continues, “enabling the ABB robot to pick it up right in the center and place it into the flights of the infeed to the Campbell flowwrapper connected to the machine.”

In one particular configuration designed for a long-standing customer, the Pro Vision system utilizes four FlexPicker delta robots that pick-and-place 360 products per minute, while pairing liquid-filled and particulate-filled clear pouches together in two-component, ready-to-mix granola mix packs.

“There was nothing like that available in the market,” Follows notes, “so we had our engineers develop it.

“We have some brilliant young engineers working here,” he says, “as well as some older engineers that are very happy to share their knowledge and expertise with them.”

The new high-speed hygienic design packaging system assembled at Propack is capable of throughput speeds of up to 200 pieces per minute to offer co-packers running a variety of products and cartons a highly flexible and cost-effective automated packaging solution.

As with the ProVision cameras, all the special robotic tooling and accessories used in the system have been 3D-printed to match the customer’s exact product handling specifications with minimal changeover requirements, according to Follows.

As Follows relates, 3D printing capabilities provide an important competence for Propack’s technicians to design and produce various machinery components designed to help its machinery maintain the highest possible sanitary standards.

“Sanitation is everything,” Follows states, citing the company’s new Propack machine—incorporating four FlexPicker robots—featuring stainless-steel frames and smooth contoured surfaces.

Designed for continuous 24-hour pick-and-place operation at speeds of 200 pieces per minute in +3°C environment, the robust machine features an IP69K rating and features an array of 3D-printed colour-coordinated components and tooling with simple snap-in-place installation and removal for cleaning and maintenance.

“We can’t have any points along the machinery where bacteria can harbor,” Follows explains. “All of our equipment that we’re producing here is fully hygienic, with machines that can be completely disassembled for cleaning and sanitation, and then quickly reassembled.

“Efficiency and sanitation are the two biggest issues facing machinery suppliers today,” Follows states, “and Propack has been strategically developing patented technologies to provide our customers with enhanced automation capabilities.

“As a result, Propack has a unique market position because our machines are amongst the fastest and most efficient in the world, coupled with the flexibility to run a variety of different products with quick, inexpensive changeovers to provide our customers with robust and reliable packaging solutions to meet their specific needs.”

A high speed flow-wrapping machine from Campbell Wrapper Corporation used in conjunction with Propack’s equipment for many turnkey line integration products.

While Follows himself describes Propack as a “mid-sized company,” there is no doubt that the company is preparing itself for continuous robust growth in coming years.

As Follows points out, the 3.5-acre site owned by Propack in Beamsville offers plenty of space for future expansions, while the firm’s physical proximity to premier vocational training institutions like Brock University, Niagara College, McMaster University and Mohawk College—all located within a 20-minute drive—ensures access to a pool emerging young talent to take care of any future staffing needs.

That factor is bound to become ever more important as the company continues to focus its activities on new business opportunities in promising growth markets such as non-food consumer goods and convenience items, personal care products, and frozen and pet food markets.

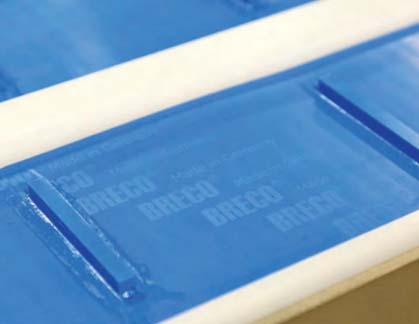

A close-up of the signature-blue BRECOflex polyurethane belting used for product transfer inside the Propack workcells.

More innovative machine parts and subsystem assemblies made with Propack’s in-house 3D printing systems.

As Follows confides, “Propack invests money into R&D without the pressures of quarterly thinking—that’s the big advantage of operating a privately-held company with a vision.

“The packaging technology is continually moving forward and changing, and we’re here to adapt to it and ensure that we’re continuing to supply the market not with just leading-edge technology, but truly cutting-edge technology,” he concludes.

“With the technology and the team we have here at Propack, we will continue to listen intently to our customers and customize our machines to meet their requirements.”

Recent Comments