Propack Sales Inquiry

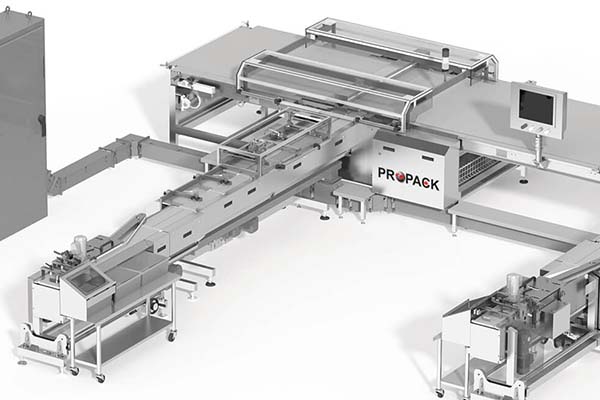

Propack Row Distribution System

Propack Row Distribution System: RDS, 700 PPM PER OUTFEED LEG (25 rows/min x 30 products per row)

The Propack Row Distribution System is an economical, safe product delivery system that empowers the use of AC motors and servo technology to receive rows of products from upstream Processing equipment and synchronizes product delivery on-time, on-demand to low, medium, or high-speed wrapping machines.

The row distribution is accomplished by intelligently monitoring product row position (bars, cookies, snacks, etc.) on a number of motion-controlled delivery sections feeding anywhere from a single or up to six wrapping machines. The Propack RDS can be configured to user-defined requirements accommodating either direct delivery, accumulation or automated refeed back into the system without operator intervention using integrated communication throughout the line.

Experience the Benefits of Row Distribution System

- Flexible with capability of handling product ranges from 2” up to 8” in length, products as thin as 0.25”

- Precise product speed and position control using state of the art Rockwell components

- Accumulation area for WIP storage to minimize operator intervention or handling of products

- Ability to refeed full rows or, (unique to Propack) the capability to refeed products between rows using servo controlled linear actuator

- Configurable to balanced distribution across multiple legs, or primary lanes with redundancy

- Safe handling of products onto downstream equipment such as Chicane laners or Wrappers

- Product specific recipes accessible via either single Panel View Plus HMI or multiple auxiliary stations located on each discharge leg

Features:

- Sanitary design for easy clean-up and accessible for maintenance

- Multi-axis Integrated on-board Servo Drive control

- Maximum product rates of 750 PPM (single) per outfeed leg

- Sanitary stainless-steel frame standard construction

- Laser etched component labelling for easy installation after sanitation

- Rockwell AC motors and servo technology

Sanitary Design

Propack systems meet and exceed every aspect of the sanitation requirements for the food processing industry.

Flexibility

Innovative and flexible designs ensure specific and unique customer needs can be met.

World Class Support

From our knowledgeable support team to our highly skilled engineers, Propack offers ongoing support both on and off-site.

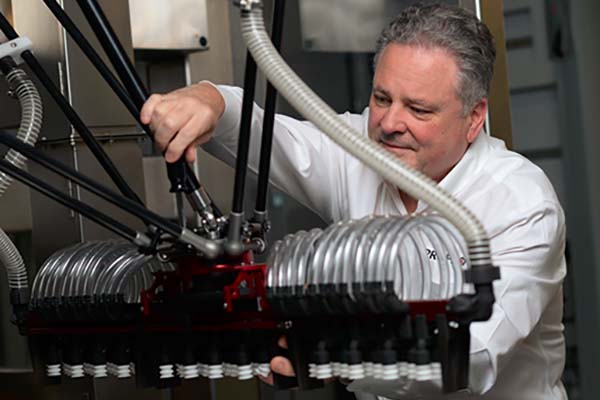

Your Carton Loader Always Features an ABB Robot

Your Propack carton loader features an ABB picking robot which will handle your product with a smooth and gentle action, keeping it free from damage. Be assured that your product will be placed precisely into your carton or tray with unmatched accuracy. For years, Propack has been proud to be part of the ABB Robotics Preferred Partner Network. At the end of the day, you can be assured that your carton loader from Propack will provide the ultimate performance for your packaging operation.